EPN Solutions offers complete solutions for industrial projects from planning to completion. With our expertise in contracting and project management, we can take responsibility for the entire process according to various contracting forms.

We execute projects according to AB04 where the client is responsible for the design and we perform the work according to the specified requirements.

Through design-build contracts (ABT06, ABA99) we take responsibility for both design and production, providing a streamlined process with a single point of contact.

With partnering we work in close collaboration with the client throughout the project, creating flexibility and enabling continuous improvements.

We deliver custom-adapted machinery and equipment according to NLM10 for industrial applications.

Every project goes through a thorough process to ensure the highest quality and efficiency.

We begin with a thorough feasibility study to understand the project's requirements, challenges and opportunities. This includes site visits, risk assessment and preliminary cost calculations.

We develop detailed plans and drawings for the project, focusing on functionality, quality and cost-effectiveness. All technical aspects are coordinated through our integrated design process.

During the production phase we execute the work according to plan, with careful control of quality, safety and schedule. Our experienced team handles all aspects of construction and installation.

Every project undergoes extensive testing to ensure that all systems function according to specification. We handle commissioning and handover to ensure a smooth transition.

See examples of successful projects we have completed for our industrial clients.

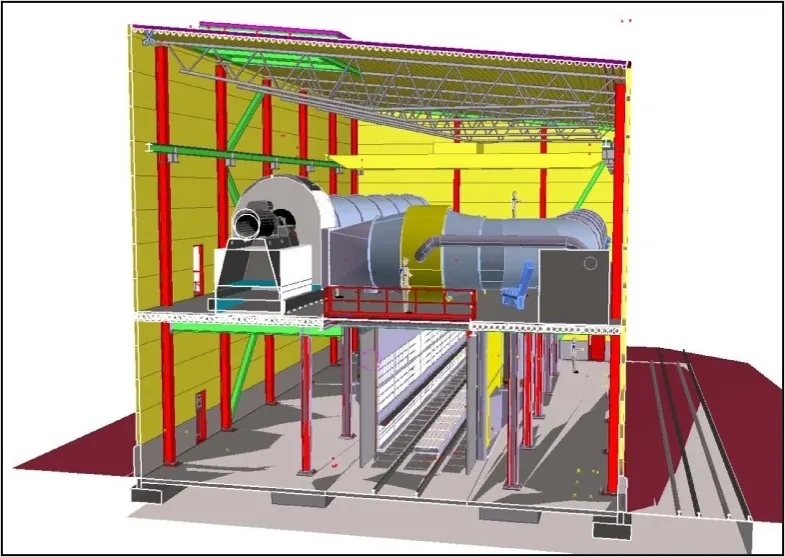

Complete design and delivery of pellet discharge system for LKAB Kiruna. The project included construction and installation according to ABA99.

Complete design and delivery of wagon tippler for unloading iron ore concentrate from ore wagons. The project included manufacturing, installation and commissioning.

Construction and delivery of 7 scrap baskets for emptying scrap into electric arc furnace. The scrap baskets have a volume of 83 m³ and a capacity of 90 tons of scrap.

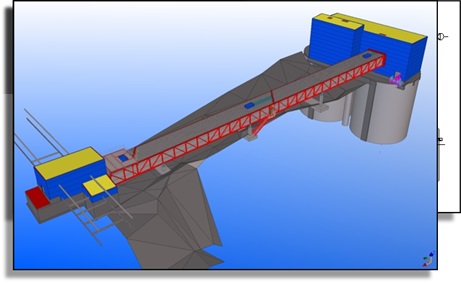

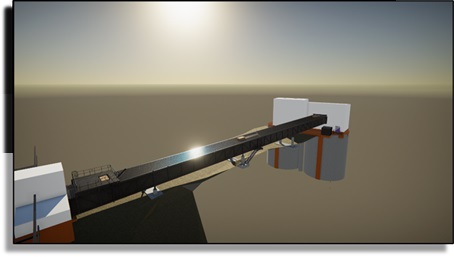

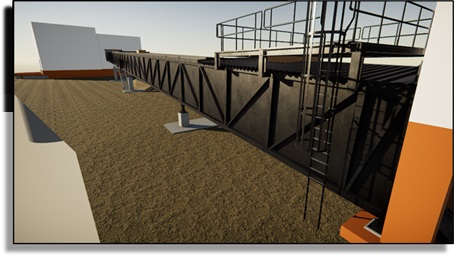

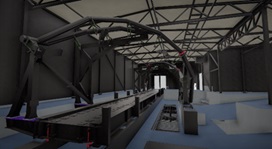

Complete delivery of conveyor gallery with 4 conveyors for efficient material handling in LKAB's facility in Kiruna.

We develop and deliver products that are optimized for efficient material handling in industrial environments.

Complete design and delivery of facilities for unloading ore wagons and other rail transports, with focus on safety and efficiency.

Specially constructed scrap baskets with high load capacity for efficient handling of metal scrap in steel mills and recycling facilities.

Belt conveyors and transport solutions for efficient movement of material in industrial facilities.

Custom-tailored facilities for storage of industrial materials, with optimized capacity and access for increased operational efficiency.

Customized equipment for specific industrial needs, developed with focus on functionality, durability and user-friendliness.

Contact us for more information about how we can help your company with custom solutions for industrial projects.